Colored Fiberglass Silicone Rubber Coated Glass Fiber Fabric

Basic Info.

| Specification | fiberglass |

| Trademark | SEIT |

| Origin | China |

| HS Code | 3925900000 |

| Production Capacity | 50000 PCS 1 Month |

Product Description

Product Description

Hand lay-up process Glass Fiber Train parts!

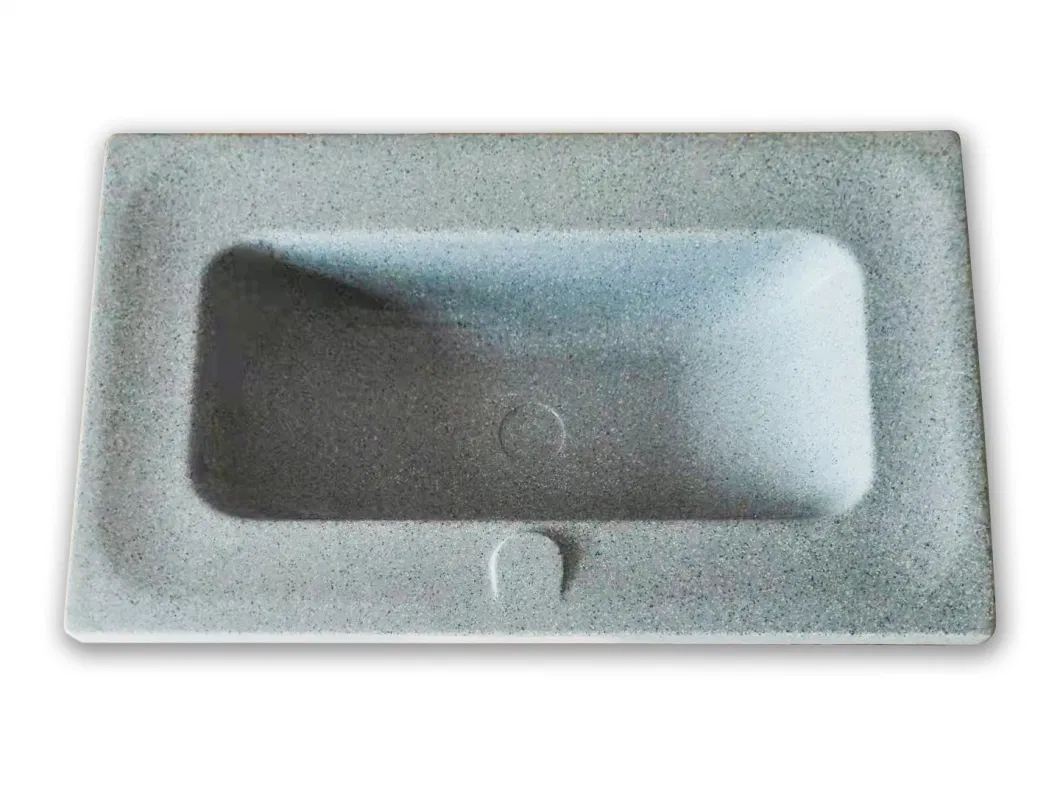

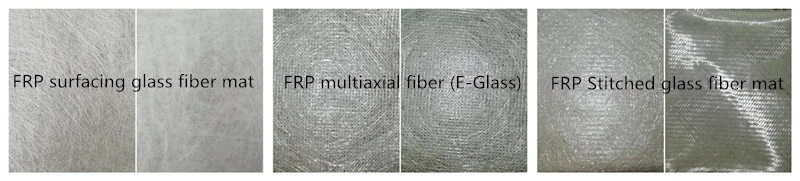

Applying a resin mixture containing a curing agent to the mold, and then laying a layer of the fiber fabric cut as required, pressing the fabric with a brush, a pressure roller or a doctor blade to uniformly dipping the rubber and removing the bubbles, and then The resin mixture is applied and a second layer of fiber fabric is applied, and the above process is repeated until the desired thickness is reached. Then, it is heated and solidified by a certain pressure (hot press forming) or solidified by heat generated by curing of the resin system (cold press molding), and finally demolded to obtain a composite product. The advantages of the process1. The molding is not limited by the size and shape of the product, and is suitable for the production of products with large size, small batch size and complicated shape. 2. Simple equipment, low investment and quick results. The process is simple, the production technology is easy to master, 3. The product has high resin content and good corrosion resistance.Details Images

| Glass Fiber + Resin System | |||||

| Part No | Resin Base | Application | Temperature resistance | Corrossion resistance | Flame resistance |

| VE | Vinyl Ester | Superior Corrosion Resistance and fire retardant | Very Good | Excellent | Very Good |

| ISO | Isophthalic Polyester | Industrial grade corrosion resistance and fire retardant | Good | Good | Good |

| ORTHO | Orthophthalic resin | Moderate corrosion resistance and fire retardant | Common | Common | Common |

| EPOXY | EPOXY Resin | ||||

Main product Pultrusion process

FRP Roofing Sheet Protruded Profile High Voltage Products 1. Shape could be customized 1. All shape of Profile 1. Under 1800KVA 2. Various kinds of FRP roofing 2. Customized performance: UV /Fire proof etc. 2. Protruded profile or Hand layup shell 3. High Quality and long service life 3. Max size: 800mm*300 (W*H) 3. Cross Arm

Molding process

Molded Gratings SMC Moulding Box GRP Sectional Water tank

1. Use: Platform, Drainage, Fence 1.3000T Hydraulic Press 1. Leak-proof, long service life 2. Advantage: Anticorrosive, Anti fire 2. Professional Design Support 2. Large size customization AvailableHand lay-up process

FRP Fish tank FRP flower pot Medical equipment shell

1. Customized color 1. OEM and ODM service 1. Customized shell

2. Large size customization Available 2. Large size customization Available 2. OEM and ODM service

3. Small Quantity Order acceptable 3. Small Quantity Order acceptable 3. Small Quantity Order acceptable

Our Company

Shengze is a leading and profession manufacturer of fiberglass products for over 20 years. The main products are various kinds of FRP pultrusion profiles, SMC products , FRP hand lay out product and vacuum infusion products. The annual production capacity is about 8,000 tons.

Our Services & Strength

Main Processing Technic Products Advantage

1. Protruded Profile 1.High Voltage Protruded profile and Hand Layup Shell

2. SMC Moulding Products 2.Customize SMC Moulding Products and Design Support

3. Hand layup Products 3.Customize Large size Hand layup Products

FAQ:

Q: Are you trading company or manufacturer ?

We are factory at specialize at fiberglass over 23 years.

Q:Can you do the production as customized?

Yes, we have a professional technique team,

we could produce the fiberglass depends on your requirements.

Q: What is your minimum order quantity?

Our MOQ is 1 PCS.(Without limiting sizes and specification,according to actual situation)

Q: How can I get samples to check your quantity?

We can offer samples for free.Pls feel free to check with me.

Q: How long is your delivery time?

Generally it is 7-10 days,depend on different products. check with me.

Q:How to pay ?

Usually by T/T , L/C , Paypal, Western Union also ok.

Contact us: